Vinegar Generator, Plant for the fermentation of 5 to 100 litres of mash into high quality vinegar.

Preis 998€

Schmickl vinegar reactor

- You can make vinegar of the highest quality with the vinegar reactor that we developed ourselves.

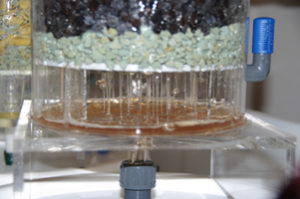

- The way it works is based on the Generator process: in a fixed-bed reactor, the vinegar bacteria colonize filling material and are sprayed with the fermentation medium at certain times.

- Essentially, activating the filling material is relatively easy: operate the reactor for several days with the fermenting vinegar so that the bacteria can colonize the packing material. The fermentation medium can then be replaced with alcohol. As soon as this has been converted into vinegar, replace the vinegar with alcohol again, and so on.

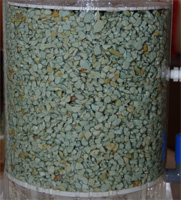

- The handling of the vinegar reactor is also described in detail in the book “The Artisanal Vinegar Maker’s Handbook”. For flavorful mashes, wine or beer, for example, inorganic, neutral-tasting materials such as zeolites are best suited as filling material.

- The addition of aromatic substances during the vinegar fermentation makes our vinegar system unique in the world.

- If aromatic substances are put into the reactor as well as the neutral-tasting filling materials, an incredible diversity of possibilities open up for the greatest variety of flavors. Depending on the desired flavor intensity and the respective material, approximately 10 – 90% of the reactor volume can be filled with herbs, spices, dried fruit and so on. Or as used to be common you could use only pure beech wood shavings (possibly smoked) in order to give your self-fermented vinegar a special flavor.

- The flavor of captive-fermented vinegar is neither like pure fermented vinegar nor infused vinegar. The vinegar bacteria colonize the aromatic filling material, which means the fermentation process takes place directly on the filling material, as can easily be seen in the following picture.

During the process, flavorings and aromatics are released like those of conventional fermented vinegar, however during the vinegar fermentation of the alcohol fermentation, i.e. the second fermentation stage, and not just in the first stage,. With conventional fermented vinegar, “only” the alcohol is converted into vinegar in the second fermentation stage. Flavorings and aromas come exclusively from the mash. Moreover, since this is filtered before the vinegar fermentation, the flavor certainly cannot increase during the vinegar fermentation. The taste of captive-fermented vinegar also differs from infused vinegars because as described the flavor carryover is not based solely on extraction (dissolving out of certain substances by a solvent). With dry fruit, even if the fruit only contains very little sugar, the vinegar becomes more full-bodied and milder than with pure infused vinegar.

During the process, flavorings and aromatics are released like those of conventional fermented vinegar, however during the vinegar fermentation of the alcohol fermentation, i.e. the second fermentation stage, and not just in the first stage,. With conventional fermented vinegar, “only” the alcohol is converted into vinegar in the second fermentation stage. Flavorings and aromas come exclusively from the mash. Moreover, since this is filtered before the vinegar fermentation, the flavor certainly cannot increase during the vinegar fermentation. The taste of captive-fermented vinegar also differs from infused vinegars because as described the flavor carryover is not based solely on extraction (dissolving out of certain substances by a solvent). With dry fruit, even if the fruit only contains very little sugar, the vinegar becomes more full-bodied and milder than with pure infused vinegar.

- Naturally the fermentation can be stopped at the usual acid content of approximately 5 – 6%. However, it makes sense to go up to approximately 10% acid or more by adding fruit spirits or high-proof mash, so that at least three-quarters of the reactor is filled with aromatic filling materials. The flavor and aroma are then so intense – a strong fragrance exudes from the vinegar bottle into the entire room just by opening it – that only a few drops are needed for seasoning.

- Delivery contents:

- Plexiglas reactor for 5 liters of filling material (L x W x H: 22 x 22 x 43 cm) with 2 pedestal plates, drain nozzle, special conically shaped base plate for complete vinegar drainage, ventilation nozzle, 4 holders for perforated plate, top plate with sealing ring

- Reactor lid of Plexiglas with filling nozzle and O-ring

- 4 hex head screws with wingnuts

- 3 air-permeable screw tops

- U-tube with knurled nuts, tap and hose nozzle

- 2 silicon tubes

- Perforated plate, fine

- Perforated plate, coarse

- Digital probe thermometer

- Clamp connection for thermometer, three-part

- Spray head, four-part

- Clamp connection for reactor outlet nozzle consisting of a threaded tube, hexagon nuts, clamping ring, white sealing ring, black sealing ring, knurled nuts

- Transfer pump, 220 V

- Timer

- 5-litre bucket filled with special zeolite

- 18-litre oval bucket with lid

- Detailed instruction manual

- Filling volume:

- With the oval bucket (included with delivery): 5 to 15 liters

- However, another container up to max. 100 liters can be connected to the reactor.

- Time required for the vinegar fermentation in the reactor: depending on the filling quantity, 4 – 14 days.

- Dimensions: W: 40 cm, D: 30 cm, H: 80 cm

Advantages over the surface process

- Provides much better results from a quality perspective.

- No vinegar eels appear.

- No musty/urine-like odor defects.

- Mother of vinegar is no longer formed.

- The daily alcohol decrease rates and acidity increase rates are about ten times greater.

- Fermentation often begins within 48 hours.

- Alcohol loss due to evaporation is negligibly low.

- Less space is needed because the fill level in the container is no longer relevant.

- Higher quantities can also be produced without enlarging the reactor. For example, the reactor can also be operated with a 100-liter barrel.

- The progress of the fermentation can be easily checked by the reactor temperature.

- The entire apparatus does not need to be opened to add or remove the fermentation medium.

- The entire fermentation medium can be replaced without interrupting the reactor’s operation.

- Operating times of multiple months or longer are possible.

- Depending on the type of filling material used, the vinegar can obtain a particular flavor. Naturally flavorless filling material can also be used.

- Herbs, spices, and fruit can also be added without first undergoing alcoholic fermentation; the vinegar flavor is markedly fuller and smoother than in infused vinegar.

- The acetic acid content can be raised above 10%.

- Filling material can be frozen and used as a fermentation starter for future use.

- The finished vinegar is generally clear and free of the cloudiness that can appear when using surface processes.

- Considerably less sensitive to the alcohol content reaching zero. Surface methods allow no leeway here. As soon as 0.0% ABV is reached, fermentation ceases and cannot be restarted by just adding alcohol without a fermentation starter, etc.

- Producing high-quality “exotic” vinegar varieties is possible. This cannot be satisfactorily accomplished with submerged processes, and cannot be accomplished at all with surface processes.

- In contrast to submerged processes, foaming media such as beer can also be fermented into vinegar.

- Reactor processes therefore also provide an alternative to professional large-scale vinegar producers, which usually work using the submerged process.