Still LEONARDO® Flexi 2, 2 Liters & 5 l / 12 l Plant Volume, according to plans by Leonardo da Vinci

Preis 933€

LEONARDO®still Flexi 2

One distilling device – two sizes: You can fill the still either with 5 liters or 12 liters of plant material. Thus, the still size fits to the amount of plant material you have available, just remove the middle part of the size. All necessary parts are in the scope of delivery.

Kettle size, filling volume, distillation time

- Filling volume, water: 1.5 – 2 l

- Filling volume, material to be distilled (vapor space): 5.0 or 12.0 liters

- Remaining vapor space: 0.5 l

- Distillation time with an electric 1500 W single hotplate: 35 to 45 minutes (including the heating-up time)

- Dimensions (maximum): width 27 cm, length 41 cm, height 58 cm

Description

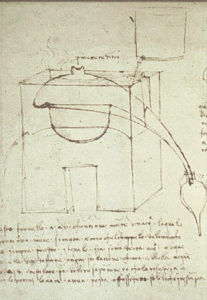

- The still is made of solid, high-quality copper. The LEONARDO® still was designed by us and is optimally designed from a process technology perspective. It is manufactured exclusively for us. The still corresponds to the construction plans of Leonardo da Vinci from the 15th century for making essential oils and hydrosols with the highest possible yield.

- Filling volume of water is 2 liters, therefore the still is free of registration!

- The still can be filled with 5 or 12 liters of plant material. The size can be changed very easily, thus you can operate the device with two different filling volumes (original Malle-Schmickl distilling devices system), avoiding empty inner space, which would result in lower yield and reduce the intensity of the hydrosol. Both sizes are included in scope of delivery.

- There is a flavor basket above the bottom of the kettle. Hence, the material being distilled, i.e. the flowers, herbs, seeds, roots or other plant materials, does not come into contact with the water during distillation, only with the STEAM. This results in particularly high-quality essential oils and hydrosols.

- The cooler has inlet and outlet nozzles for connection to a water tap. On the inside the inlet nozzles reach down to the bottom of the cooler in order to ensure complete circulation of the cooling water. To go with this, a meter-long piece of silicon tube is included. Tube connectors and tubes with different diameters are available in DIY markets and aquarium shops. It is also possible to operate the cooling system by means of a recirculation pump (not included in delivery), similar to indoor fountains. The cooler is open on top, so it is also possible to operate the still without running water. In this case, simply pour cold water into the cooler from the top in order to exchange the cooling water.

- Due to the flat kettle bottom, the still can be placed directly on a gas or electric stove. No additional burner is required. A wood stove (kitchen stove) or open fire are naturally also suitable as heat sources.

- When the individual parts are connected together, the still is sealed, and no replacement parts or gaskets are required.

- The stills are handmade, each LEONARDO® is in fact unique

- The still is delivered with detailed operating instructions.

- The vapor condenses in a copper dome (topmost container). Due to this short vapor and cooling path, a very rich hydrosol is created, and there are no losses of the valuable oil during cooling, as there are for example in a cooling coil.

- With the LEONARDO®, the complete interior including the cooler and run-off groove can be reached by hand. Therefore the still can be cleaned effortlessly on the inside and outside without any residue in no time at all with a cleaning sponge and dish soap. Nothing is more annoying than impurities in the distillate simply because certain areas of the still are not accessible. The best thing for cleaning the distillate drain tube is the matching tube brush.

- The still deliberately has NO automatic oil separator or separating funnel. First of all, this is because considerable quantities of oil stick to the insides of this type of equipment, so no oil is lost unnecessarily. Secondly, because some oils are heavier than water (e.g. cinnamon, cloves, alant root, balsam poplar and so on), and thirdly because the container with the hydrosol and essential oil should be stored for at least several weeks BEFORE separation in order to obtain the highest possible quality oils and hydrosols. Apart from this, the hydrosols obtained from the LEONARDO® are so intensive that , depending on the plant type, they often exhibit very opaque and milky cloudiness, or there are accumulations of oil drops in the bottom area. Hence, with automatic oil separation, considerable amounts of the valuable oil would not be separated. Even with crystal clear hydrosols, you should wait at least several hours before you separate the oil from the hydrosol.

- In our book The Essential Oil Maker’s Handbook (not included in delivery), you will find many tips and guides that go far beyond the operating instructions such as, for example, the right part of the plant, the optimum harvest and harvesting time (time of day) and the best processing methods for more than 140 native and exotic plants in order to obtain the most intensive hydrosol possible and high oil yields. Furthermore, there are more than 50 basic recipes for using the essential oils and hydrosols. The selection ranges from products for facial and body care, liqueurs, spiced oils, flavoring for tea, and inhalations to room sprays, sauna infusions and perfume

Coil Condenser or Dome Condenser?

- For alcohol distillation, the included coil condenser is best suited due to its strong cooling performance. An extremely reliable condenser that covers all areas of alcohol distillation.

- For producing essential oils and hydrosols, however, this type of condenser has the disadvantage that small oil quantities (a few drops) may remain in the coil, which — especially with plants with low oil yield (roses, lemon balm, German chamomile, many wild herbs) — may represent the entire yield. When distilling plants with higher oil content, such as lavender, the oil yield with the 5-liters kettle is 15–20 ml. In such cases, the loss in the cooling coil is of course negligible. After distillation, the coil can be cleaned by flushing, for example with high-proof alcohol (at least 80 %ABV). A dome condenser, on the other hand, has the advantage that the entire oil runs into the receiving bottle without losses, and that this condenser can be easily cleaned by hand on the inside (!!!) — simply with dishwashing detergent and a cleaning sponge.

Possible Variations

- The coil condenser and the dome condenser from the Suprema-Flexi product line (see SUPREMA and LEONARDO® Flexi stills) can be combined with other unit parts as follows: